What is a U-shaped tube heat exchanger? What are the differences between U-shaped tube heat exchangers and other heat exchangers?

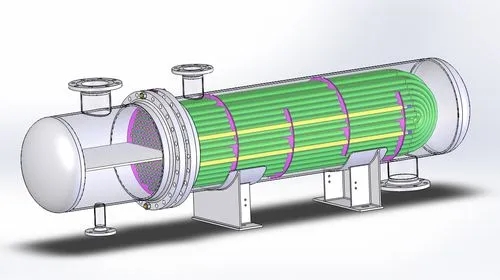

U-shaped tube heat exchanger, each tube is bent into a U-shaped shape, and both ends are fixed on the same tube plate. Each tube can be freely extended and extended to solve the problem of thermal compensation. The tube has at least two passes, the tube bundle can be removed for cleaning, and the tube can expand freely. Its disadvantages are difficulty in cleaning the inner wall of the pipe, difficulty in replacing the pipe, and fewer pipes arranged on the pipe plate. The advantages are simple structure, light weight, and suitability for high temperature and high pressure conditions.

Spiral plate heat exchanger is an efficient heat exchanger equipment suitable for steam liquid, steam liquid, and liquid liquid heat transfer. It is suitable for industries such as chemistry, petroleum, solvents, pharmaceuticals, food, light industry, textiles, metallurgy, steel rolling, coking, etc. According to the structural form, it can be divided into non detachable (Type I) spiral plate heat exchangers and detachable (Type II, III) spiral plate heat exchangers.

Tube and tube condensers are divided into three types based on material: carbon steel tube and tube condensers, stainless steel tube and tube condensers, and carbon steel and stainless steel mixed tube and tube condensers. Classified by form, it can be divided into tubular condensers, spiral plate heat exchangers, floating head heat exchangers, and U-shaped tube heat exchangers. Divided by structure into single tube condenser, double tube condenser, and multi tube condenser. Heat transfer area of 0.5-500 square meters. Customizable according to user needs. Suitable for heat exchange equipment used in various industries such as chemical, light industry, metallurgy, pharmaceuticals, food, and chemical fibers, especially suitable for use as condensers, replacing existing stainless steel condensers, enamel condensers, graphite condensers, and glass condensers. The effect is significant after use.

One tube plate of a floating head heat exchanger is connected to the outer shell by a flange, while the other tube plate is not connected to the outer shell, so that the tube can freely expand and contract when heated or cooled. However, a top cover is connected to this tube plate, which is called a "floating head".

Therefore, this type of heat exchanger is called a floating head heat exchanger. Its advantage is that the tube bundle can be pulled out for easy cleaning; The expansion of the tube bundle is not constrained by the shell, so when the temperature difference between the two heat exchanger media is large, there will be no temperature difference stress due to the difference in thermal expansion between the tube bundle and the shell. Its disadvantages are complex structure and high cost.